In industrial production, the uniformity of material mixing directly determines the quality and performance of the final product. Whether it is the raw material proportioning in food processing, the component integration in the chemical industry, or the texture control of architectural coatings, the word "uniformity" has always been a core requirement. The inclined dynamic shearing and convective mixing equipment developed by Shandong Enweisen Machinery Technology Co., Ltd., relying on its unique technical design, turns "extreme uniformity" from an ideal into reality, and has become a trusted choice for customers in various industries.

1. Inclined Structure: Eliminating Mixing "Dead Zones" to Keep Materials "In Motion"

Most traditional mixing equipment adopts a vertical tank design. Under the action of gravity, materials tend to deposit at the bottom of the tank, forming hard-to-stir "dead zones" and leading to uneven mixing. Enweisen innovatively adopts an inclined tank structure. Through a scientific inclination angle setting of 15°-30°, materials remain in a "flowing state" throughout the mixing process. The inclined angle of the tank guides materials to continuously slide and flip along the tank wall, preventing local materials from being stationary for a long time and laying a foundation for "uniform mixing" from a spatial perspective.

More importantly, the inclined tank and the mixing system work in synergy: when the mixing components operate, the inclined structure can expand the convective range of materials, allowing materials with different densities and particle sizes to quickly move through all areas of the tank, completely eliminating the industry pain point of "local mixing meeting standards but overall unevenness".

2. Dynamic Shearing: Breaking Down "Agglomerated Particles" for Micro-Level Uniformity

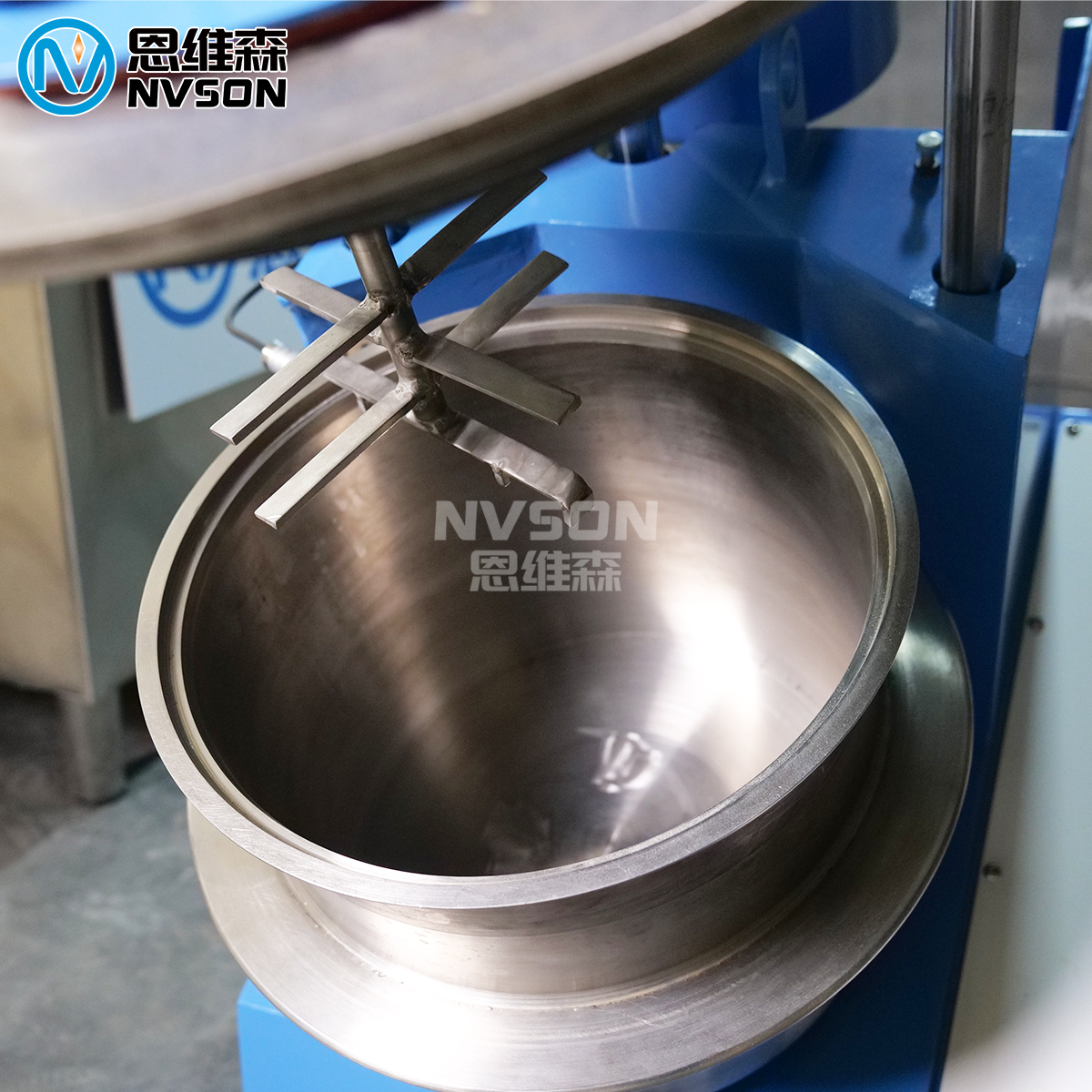

The difficulty in material mixing often lies in the easy formation of "agglomerated particles"—especially for powders and high-viscosity materials. The adsorption force between particles leads to caking, which is difficult to break up by ordinary stirring, thereby affecting mixing accuracy. Enweisen's inclined mixing equipment is equipped with a high-speed dynamic shearing system. Through a built-in multi-layer shearing knife set, it performs "precision shearing" on materials at an adjustable speed of 1000-1500 r/min.

When materials flow through the shearing area, the high-speed rotating knife set generates strong shearing force and turbulent effects: on one hand, it breaks down large agglomerated particles into fine particles, ensuring that each particle can participate in mixing independently; on the other hand, the local high temperature (within a controllable range) generated during the shearing process can soften high-viscosity materials, reduce the bonding force between materials, and enable full contact and integration of materials with different components at the micro level. This logic of "breaking first, then mixing" enables the mixing uniformity to reach over 98%, far exceeding the industry average.

3. Convective Mixing: Enhancing "Material Exchange" to Accelerate the Overall Uniformity Process

If dynamic shearing solves the problem of "micro-particle uniformity", then the convective mixing design achieves the efficiency of "macro-material exchange". Enweisen has installed a special combination of spiral guide plates and mixing paddles inside the inclined tank. When the mixing paddles operate, they drive materials to perform "vertical convective movement" along the axial direction of the tank, while the inclined structure guides materials to perform "circular movement" along the radial direction, forming a "three-dimensional convective flow".

This multi-directional material movement mode increases the material exchange speed by more than 30%: lighter materials will not always float on the top, and heavier materials will not deposit at the bottom. Instead, they continuously intersperse and penetrate under the action of convection, achieving overall uniformity in a short time. Taking the mixing of flour and additives in the food industry as an example, traditional equipment takes 10-15 minutes to meet the standard, while Enweisen's inclined mixing equipment only takes 5-8 minutes, with more stable uniformity.

4. Practical Verification: The "Uniformity Commitment" from Laboratory to Production Line

The "extreme uniformity" of Enweisen's inclined dynamic shearing and convective mixing equipment is not just a theoretical concept, but has been verified through a large number of practical applications in various industries. In the coating production of a large chemical enterprise, this equipment successfully solved the "color difference" problem caused by uneven mixing of pigments and resins, increasing the product qualification rate from 85% to 99%; in the food processing field, it realized the precise mixing of milk powder and nutritional fortifiers, ensuring that each spoonful of milk powder has exactly the same nutritional components.

From structural innovation to technological breakthroughs, from micro-level shearing to macro-level convection, Enweisen takes "extreme uniformity" as its goal, continuously optimizes mixing technology, and provides efficient and stable mixing solutions for customers in various industries. In the future, Enweisen will continue to deepen its focus on mechanical technology, use more advanced equipment to help enterprises improve product quality, and promote the high-quality development of the industry.