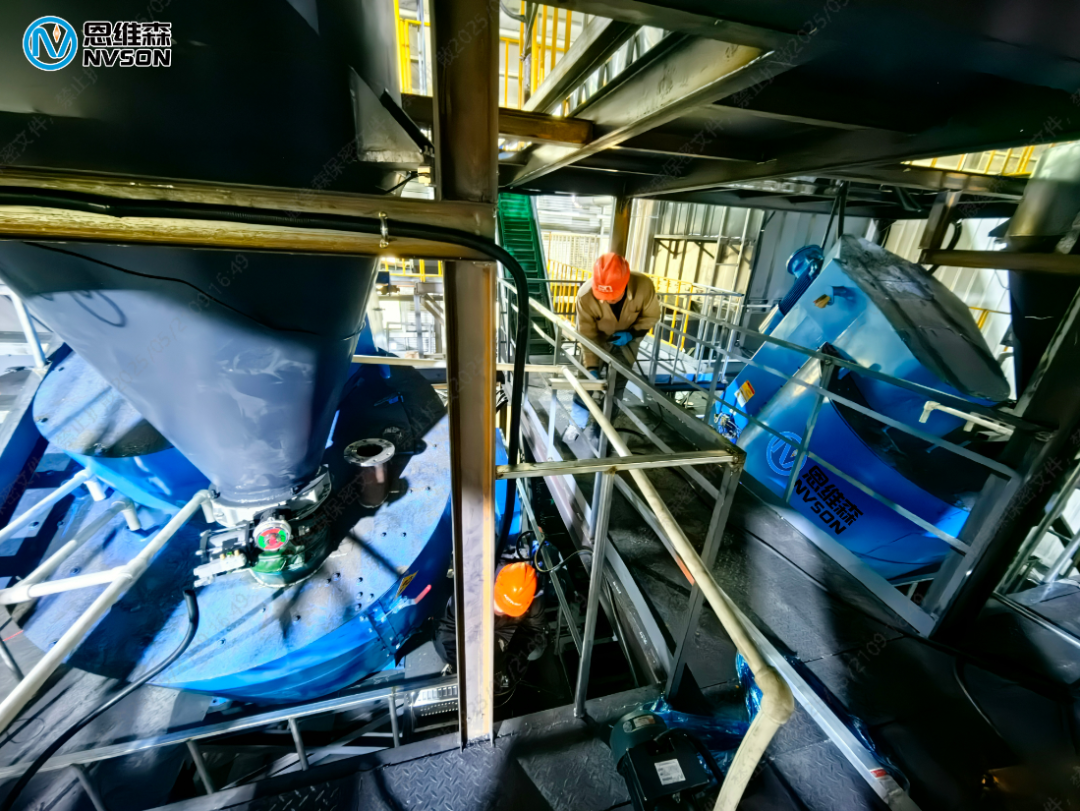

In today's era of diversified industrial production, the ability of equipment to adapt to different materials, processes, and production capacities directly affects an enterprise's production flexibility. Envison's inclined mixing granulator, with its modular design as the core advantage, easily meets multi-scenario production needs and becomes an important helper for enterprises to reduce costs and increase efficiency.

Flexible Combination of Core Modules for Various Materials

Envison disassembles the core functions of the equipment into independent modules: stirring module, granulation module, drive module, and control system module. For viscous materials (such as adhesives), stirring blades with wall-scraping functions can be replaced; when processing hard particles (such as ore powder), granulation molds made of high-wear-resistant alloy materials are selected; for hygienic requirements in food, pharmaceutical and other industries, stainless steel sterile modules can be quickly switched. Modules adopt standardized interfaces, and the replacement time is shortened to within 30 minutes, allowing one device to easily adapt to more than ten types of materials from powder to paste.

Envison disassembles the core functions of the equipment into independent modules: stirring module, granulation module, drive module, and control system module. For viscous materials (such as adhesives), stirring blades with wall-scraping functions can be replaced; when processing hard particles (such as ore powder), granulation molds made of high-wear-resistant alloy materials are selected; for hygienic requirements in food, pharmaceutical and other industries, stainless steel sterile modules can be quickly switched. Modules adopt standardized interfaces, and the replacement time is shortened to within 30 minutes, allowing one device to easily adapt to more than ten types of materials from powder to paste.

Capacity Modules Expand on Demand to Match Production Scale

Enterprise production scales often fluctuate with market demand, and the modular design enables the equipment to have "growth potential". In the start-up stage, a basic module with a single batch of 50L can be selected; when the production capacity increases to 200L per batch, only the cylinder extension module and power upgrade module need to be added without replacing the entire machine; for continuous production scenarios, by splicing multiple sets of granulation modules, the hourly capacity can be flexibly adjusted from 1 ton to 10 tons, saving 60% of the upgrade cost compared with traditional equipment.

Enterprise production scales often fluctuate with market demand, and the modular design enables the equipment to have "growth potential". In the start-up stage, a basic module with a single batch of 50L can be selected; when the production capacity increases to 200L per batch, only the cylinder extension module and power upgrade module need to be added without replacing the entire machine; for continuous production scenarios, by splicing multiple sets of granulation modules, the hourly capacity can be flexibly adjusted from 1 ton to 10 tons, saving 60% of the upgrade cost compared with traditional equipment.

Seamless Connection of Intelligent Modules for Compatible Process Iteration

With the upgrading of intelligent manufacturing, Envison's modular design reserves intelligent upgrade interfaces. Existing equipment can be directly equipped with online detection modules (such as near-infrared moisture meters), automatic feeding modules, and MES system docking modules, realizing the upgrade from "manual monitoring" to "full automatic closed-loop control". A chemical enterprise, by adding intelligent modules, shortened the process parameter adjustment time from 2 hours to 15 minutes, and the product qualification rate increased to 99.2%.

With the upgrading of intelligent manufacturing, Envison's modular design reserves intelligent upgrade interfaces. Existing equipment can be directly equipped with online detection modules (such as near-infrared moisture meters), automatic feeding modules, and MES system docking modules, realizing the upgrade from "manual monitoring" to "full automatic closed-loop control". A chemical enterprise, by adding intelligent modules, shortened the process parameter adjustment time from 2 hours to 15 minutes, and the product qualification rate increased to 99.2%.

The modular design of Envison's inclined mixing granulator breaks the limitation of traditional equipment's "one machine for one use", so that enterprises do not need to repeatedly purchase equipment for different scenarios. This characteristic of "combination on demand and upgrade as needed" not only reduces the initial investment, but also improves the production response capability, making it a flexible production partner for enterprises in multiple industries.